Date: 2025-03-14 Page is: DBtxt003.php txt00014926

Companies

CollabraTech Solutions

About Us ... Collabratech_AboutUs ... At CollabraTech Solutions

Burgess COMMENTARY

Peter Burgess

About Us

Collabratech_AboutUs

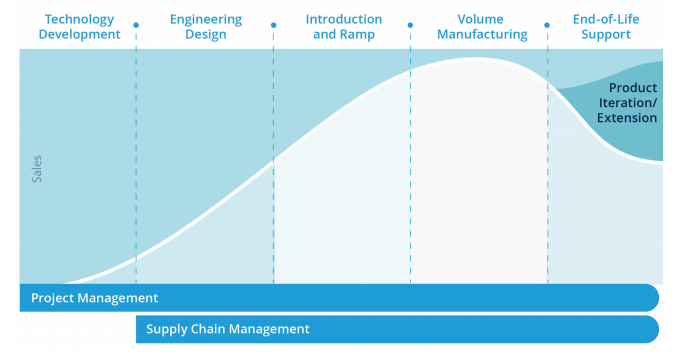

At CollabraTech Solutions, we’re breaking down barriers between traditional product life cycle practices and market realities, bridging the phases from concept to production. While theory and rules provide necessary guidelines, reality is usually too complex to fit into a generic framework. At some point, only experience can guide you. Our combined experience in engineering, manufacturing, and project management help you navigate and simplify the complex path to bring your ideas to market.

Our expertise includes development, prototyping, design-for-manufacture, down-costing, systems integration, maintenance, product extension, and end-of-life planning. Our wide-angle lens on high-tech engineering leverages real-world knowledge as an advanced, in-house contract manufacturing service organization. We know what it takes to make 10 and what it takes to make 1,000, and the rules for each. We also know that a single, hand-built prototype might be a brilliant demonstration unit, but may never qualify for a pharmaceutical production line, or use in aerospace missions.

Put CollabraTech’s expertise to work for you, and watch as time-to-market shortens, costs decrease, customer acceptance increases and profit margins improve.

Our Team

Ted Johnson, Chief Executive Officer and Board Member

Ted comes to CollabraTech Solutions with more than 25 years of experience in vertically integrated turnkey manufacturing and design execution. With his deep knowledge of operational efficiencies and a strong network in a variety of industries, Ted establishes and manages many of CollabraTech’s strategic relationships.

Ted comes from Advanced Integration Technologies (AIT), where he served in a variety of positions, including president for many years. Under his leadership, the company’s revenue grew by more than 2,000 percent. During this time, the company brought in private equity investors, acquired a leading multinational manufacturer of gas and chemical delivery systems, and eventually was sold to a publicly held manufacturer in similar industries. His story proves that hard work and dedication are the keys to success, a philosophy that he truly embraces still today. Ted started at AIT while attending Northern Arizona University, where he studied electrical engineering and business.

Ted’s belief in a relationship-based team culture was instrumental to AIT’s overall success. He brings these people-focused ideals to CollabraTech, where a collaborative approach is deeply integrated in the company’s overall vision and daily operations.

Steve Lemons, President

Known for his deep-rooted passion for building highly effective teams that provide strong results in complex environments, Steve brings a proven track record of success in leading all facets of business operations for both startup ventures and Fortune 500 multinational organizations. He has in-depth knowledge and a strong network in the semiconductor, medical, industrial and aerospace industries. Steve joined CollabraTech Solutions after eight years as Senior Vice President with Advanced Integration Technologies (AIT), where his strategic leadership of more than 600 team members in the U.S. and Asia resulted in impressive revenue growth, record profit margins and two mergers during his tenure.

Steve was also instrumental in the startup of two new technology companies, where his leadership helped to establish high-volume production capabilities, develop and implement company strategic direction, manage scale-up of operations as well as form and nurture strategic partnerships. He began his career with 10 years of engineering and operations positions with the Boeing Company. Steve holds a B.S. in Mechanical Engineering from Arizona State University, a Master’s of Engineering Management from Washington State University and an MBA from Seattle Pacific University. He has both the business background and technical training to understand the multifaceted ins and outs of technical design and streamlined manufacturing operations.

Tim Provencher, Vice President of Engineering

Tim is responsible for engineering operations and personnel while supporting the company’s strategic development activities. His technical expertise is diverse within engineering methods and fabrication techniques of custom & capital equipment systems. As an innovator, Tim has numerous patents in a broad range of industries. He holds a BSME from Wentworth Institute of Technology.

Prior to joining CollabraTech Solutions, Tim held the position of Vice President of Engineering at Advanced Integration Technologies (AIT) and its merger with Ultra Clean Technologies (UCT). With engineering excellence and customer quality in mind, he selected key engineering disciplines to architect the methods and controls that support product development. The results allow the engineering function to augment our customers engineering resources in product support or act stand-alone within a total design solution.

In addition, Tim has in excess of 25 years capital equipment experience within the Semiconductor industry. He has managed multi-national development teams for ASM International, Tokyo Electron and Materials Research Corporation for the successful launch of PVD, CVD and ALD next generation deposition platforms.

John Wheeler, Director of Product Development

John is a veteran of the semiconductor industry and has worked in equipment engineering since the early 1980s. He developed his skills in electromechanical system operations and maintenance during his time in the United States Navy. His experience in the Navy gave him the skills required for his equipment engineering position at Motorola. His eagerness to understand the equipment drove him to broaden his knowledge base and take on the challenges of process engineering for the diffusion area, followed by implant, metals and dry etch. John was given a lead role in new equipment design for Motorola’s Advanced Research and Development Laboratory, and later moved to Austin, where he managed all equipment manufacturers, equipment and facility set up to launch new operations.

In 1987, John brought his experience to Flopure (now Praxair), a startup gas equipment manufacturer, where he helped propel the company into a leading position in gas cabinets and tool upgrades for the semiconductor industry.

As an experienced leader of startup ventures, John founded Norcimbus in 1990, where he and his team of equipment engineers developed chemical delivery equipment for the semiconductor industry. Norcimbus evolved over the years to offer a full suite of products, which now are part of CollabraTech’s line of gas and liquid delivery systems, controllers and components.

Jeff Wells, Director of Business Development

Jeff brings more than 15 years of field experience in the technical sales and support of complex electromechanical assemblies and ultra-high purity gas systems to the CollabraTech executive team. By applying his engineering training, manufacturing experience and design for manufacture expertise, Jeff has been successful in delivering creative solutions to address the specific manufacturing challenges experienced by clients across multiple market segments. Throughout his career, he has built a reputation as a devoted customer advocate, ensuring customer satisfaction through strong communication and the nurturing of close business relationships. Jeff continuously strives to understand his customers’ needs, and ensures those needs are clearly communicated to all project collaborators. For him, this is the key factor in exceeding customer expectations.

Prior to joining CollabraTech Solutions, Jeff served as the Director of Business Development at Foresight Technologies and the Business Development Manager at Advanced Integration Technologies (AIT). He has the unique ability to identify, qualify and develop engineering and manufacturing opportunities. Prior to moving into a business development role, Jeff worked as both a design and project engineer in the aerospace and semiconductor fields. During that time, he served on the Board of Arizona Tooling and Machining Association. Jeff holds a B.S. in Aerospace Engineering.

Edward F. Crawford, Board Member

Edward is the Chairman and Chief Executive Officer of Park-Ohio Holdings Corp (NASDAQ: PKOH), a Cleveland-based industrial company with approximately $1.4 billion in annual revenues. Park-Ohio specializes in integrated logistics systems and manufactured products, and currently employs 4,800 associates worldwide. Edward brings his extensive knowledge and expertise in growing successful businesses to CollabraTech Solutions and his involvement in setting the company’s strategic vision is a key to future success. Edward is committed to a balanced life of commercial activity, civic responsibility and political action.

Gary Imdieke, Board Member

Gary started his career running a premier sheet metal manufacturing company before he founded American Sheetmetal Inc. in 1983. American Sheetmetal quickly became a leading metal fabricator specializing in precision sheet metal, complex frames and machining. The company supplied precision products to the semiconductor, computer electronics, medical and gaming industries and became known as the supplier that could meet difficult expectations that others could not. This success encouraged many of the customers to ask his company to expand into value added turnkey assemblies and integration. The company rebranded into AIT, continued its rapid growth and sold to a private equity partner in 2005. Gary has a passion for developing cost effective manufacturing solutions to complex problems so he served as a board member and manufacturing consultant for AIT for many years. He now brings that passion and entrepreneurial expertise to the board of CollabraTech Solutions with a strong desire to help the company grow and establish its commitment to excellence and collaborative partnerships. Gary also enjoys researching personal investments and working on a variety of mechanical projects, such as muscle cars in his home shop.

-----------------------------------------------------------------------

Medical

In an industry that is ever growing and changing, CollabraTech is your partner in navigating the complex dynamics of designing and manufacturing medical equipment. We are a proven leader in integrated product development, and we bring this same expertise and enthusiasm to the medical industry. We establish sustainable services and solutions which enable our customers to quickly and efficiently bring their designs to life…. many of which save lives.

Whether your focus is laboratory automation, clinical diagnostic hardware, analytical equipment, custom medical carts or diagnostic imaging technology, CollabraTech can provide the solution. When it comes to complex integration and testing, engineering and precision fabrication, CollabraTech is the partner you can depend upon.

CollabraTech understands how important it is to provide a full-service solution that gives you total control of your project. We provide expertise in the following areas:

High quality products including diagnostic imaging, laboratory automation, clinical diagnostic hardware, analytical equipment and medical carts

Complete product integration and test

Concurrent product development and embedded engineering

Engineering, design and frame fabrication

-----------------------------------------------------------------------

Microelectronics

CollabraTech’s unique approach to semiconductor system integration has raised the bar for the entire industry. Established by a group of individuals with extensive experience in the semiconductor manufacturing industry, the company is an industry leader in the design, engineering, manufacturing, installation and qualification of a variety of semiconductor tools, including particle-free gas and chemical delivery systems and automation.

CollabraTech provides integrated services for procurement, engineering, integration and testing for major semiconductor capital equipment. Our team is comprised of experienced engineers and technical experts in deposition, metrology, ion implant, lithography systems and more.

With state-of-the-art cleanroom manufacturing facilities, we are well equipped to handle manufacturing, logistics and supply-chain management, allowing for rapid design, assembly and distribution that is guaranteed to meet both your budgetary and quality expectations. Our dedicated, in-house training program ensures that our customers receive the highest quality product and top-notch service. Our manufacturing and cleanroom capabilities include:

20,000 square foot corporate manufacturing facility

2,000 square foot certified Class 10 cleanroom

Purified and filtered inert and specialty gases on-site

Hot deionized and cooling water

110 / 208 / 240 / 480 VAC power

The latest tube welding equipment and procedures

Fully-trained and certified weld and assembly technicians

Complete UHP product analysis

Comprehensive ERP systems to effectively manage demand

-----------------------------------------------------------------------

Industrial

CollabraTech understands the need for industrial efficiency. We thrive on finding the highest quality and most efficient way to solve your industrial manufacturing challenges. CollabraTech is your one-stop outsourcing solution to engineer, integrate and test your manufacturing systems. From factory equipment automation and enterprise rack systems to remote monitoring systems and power distribution, CollabraTech provides you the peace of mind and expertise to quickly get your manufacturing systems up to speed. Whether you need systems designed and implemented, or you pass the manufacturing responsibility to CollabraTech – we will assure you the highest quality end product.

We provide a broad range of services to customers in the transactional and informational kiosk industries, spanning across a multitude of industries and applications.

CollabraTech’s industrial manufacturing expertise includes:

Design, fabrication, assembly and integration of industrial manufacturing equipment

Complete product integration and test

Concurrent product development and embedded engineering

Engineering, design and frame fabrication

-----------------------------------------------------------------------

Commercial

With CollabraTech by your side, you can rest assured that your production needs will be meet with top quality results. Along with industrial manufacturing services, CollabraTech also offers production and fabrication for consumer goods. By implementing lean manufacturing best practices, CollabraTech offers a truly responsive environment that can effectively support the most dynamic and complex production requirements.

As supply chain experts and process innovators, we aim to ensure that from concept design to final outcome, your consumer product is completed within your design and budget specifications. Our facilities are configured to maintain lead times that are among the shortest in the industry, ensuring that your product gets into customers hands quickly and efficiently.

Consumer product manufacturing capabilities include:

Design, fabrication, assembly and integration of industrial manufacturing equipment

Complete product integration and test

Concurrent product development and embedded engineering

Engineering, design and frame fabrication

-----------------------------------------------------------------------

Life Science

The life science sector is changing rapidly, and the pace of innovation demands new technology. Those innovations require ever-more-advanced instrumentation and measurement capabilities. At CollabraTech Solutions, we know it what it takes to remain competitive in this highly complex market. Platforms must be easy to use, fast, automated, flexible and adaptable, so they can evolve to support broad applications. They must handle both the complicated and routine, and be user friendly. Floor space is at a premium in life science labs, so compact footprints are critical. Products must adhere to stringent regulatory compliance guidelines. Work with a partner that understands the constraints and guidelines of the industry and launch sooner with better products.

Whether your equipment targets biological sample analysis, DNA profiling, proteomics and disease research, or drug design and development, CollabraTech can support you through the entire process, from design and development, through prototype, regulatory compliance, ramp to production, end-of-life, and beyond.

-----------------------------------------------------------------------

Aerospace

Times have changed since NASA put the first man on the moon. The next generation of space innovation is being driven by the commercial space sector. When it comes to complexity of design and meeting stringent performance and reliability requirements, it doesn’t get much more complex than the aerospace industry. From jet engines to rockets and space station equipment, CollabraTech Solutions has the experience and know-how to take your ideas and make them take flight. Literally. We support the entire life-cycle process, from design and development through end-of-life and next-gen products. We specialize in such mission-critical areas as systems design, test and validation, tooling design and development, and more. Because sometimes it is rocket science.

-----------------------------------------------------------------------

-----------------------------------------------------------------------

-----------------------------------------------------------------------